Cider Press Upgrade: Converting my Barrel Press to Rack and Cloth.

More Cider from Fewer Apples

A bit ago, my wife and I made a very nice cider press and pressed a lot of apple cider. But there was one major problem with it: it was not very efficient. Each pressing would end with apple pulp that was still moist to the touch, and that I felt I could wring juice from merely by squeezing it in my hand. This was not acceptable, as apples are expensive, and so is my time; when I set out with a goal of pressing a certian volume, it's in my best interest to be able to meet that goal with the minimum amount of apples and pressings required.

Cider Press Efficiency Variables

There are two major, and several minor, steps that affect the efficiency of cider pressing (efficiency being the volume of juice pressed from a given weight of apples). The two major steps are the grinding, and the pressing. A finer grind, which breaks more cell walls within the apples, will produce more juice. Many older grinders produce recognizable apple chunks, while newer commercial apple grinders yield something that more resembles a puree. While my grinder is of the chunky sort, and could use an upgrade for maximum performance, it's not awful and I find it to usually be sufficient.

The other major step that affects efficiency is the pressing itself. Things like the amount of pressure exerted, the amount of surface area of apple that that pressure is applied to, the ease of juice flowing out, and more, all contribute to the amount of juice produced by some apples. The press we built last year is a barrel press, meaning it has a circular barrel into which is placed a cloth bag of ground apple. A large, circular wooden block is then placed atop the ground apple, which is pressed down to squeeze the apples and extract the juice. In the case of my press, it is a 10-ton hydraulic jack that does the pressing, though other presses may use a hand-turned screw or something else.

Press Types

There are a number of other kinds of presses out there, but the three most common are rack and cloth presses, hydro bladder presses, and belt presses. I'll discuss each in reverse order. Honesly AI could probably tell you about these better than I can, but I write these projects up for me, not for you, and to use AI on what's basically a diary feels dishonest.

Belt presses are the sort you would expect to see at a large, commercial cider factory. The very smallest of them cost well over $10,000. They have a large, porous belt onto which ground apple is fed, and the belt then is brought against another belt, and as the belts go around a roller, the tensioned belts apply pressure to the apple, squeezing out the juice. The belts then separate, dumping the spent apple. These are very efficient presses for juice, as they can exert high pressure, the large belt area means that the pressure is applied across only a thin layer of apple, and since the belt is porous, the juice can escape immediately. But the largest benefit of a belt press is that it can run continuously, accepting ground apples at one end, squeezing out the cider, and ejecting the spent pomace out the other end without stopping. As mentioned above, the main downside is cost.

Hydro bladder presses are very easy to use, and are efficient. They are constructed of a metal barrel with thin slats for the juice to flow through, inside which sits a large neoprene water bladder. The apple pulp is put into a filter bag in the barrel around the bladder, and a hose is connected to the bladder and turned on. Water fills the bladder, inflating it, and the water pressure will push the pulp against the metal cage, pressing out the juice. Benefits include very simple cleanup, minimal labor, and capacity. A 40-liter press will run you about $1000 as of this writing (late 2025), while a rack-and-cloth capable of 40 liters in one pressing will run you much more unless you make it yourself. Downsides are that it's not as efficient as a belt or rack-and-cloth press (but still better than a basket press!), and each pressing will use a large amount of water, which must be drained to do another pressing; without some way to reuse it, you'll be wasting many gallons of water per pressing.

Finally, rack and cloth presses! This press is similar to a basket press is some ways; starting with a grating at the bottom, but instead of placing a basket on this grating, a square form is used instead. A square cloth (polyester or cotton) is placed over the form, and the covered form is filled with apple pulp. When the form is full, the corners of the cloth are folded inwards, covering the pulp and exposing the form. The form is removed, and a flat piece of material called a "rack" is placed on top of the square of bundled pulp. The form is placed onto the rack, and the above steps are repeated, until the operator runs out of racks or runs out of vertical room in their press. When this happens, they begin pressing downwards with a hydraulic jack, screw, or other mechanism to press out the juice. A basket press is a very inefficient shape for pressing apples; the apple pulp in the center of the basket has a long distance to travel in any direction in order to reach the outside of the bag of pulp to be collected, and frequently the center of such pulp is quite wet. With a rack and cloth press, the surface area of apple pulp is maximized, and juice travel distance minimized. Thus, rack and cloth presses can produce upwards of 15% more juice from the same amount of apple pulp.

There's of course also the basket press, which our press originally was; see the linked post in the first sentence of this page for images. We learned empirically that they come with an assortment of issues, such as low press efficiency, constant tears in the pressing bags containing the apple pulp, and the press block rotating slightly and jamming inside the basket.

The Upgrade

After our first pressing season with the original basket press proved a bit lackluster in terms of the amount of juice yield per unit apple, we decided an upgrade was in order. A rack and cloth press is structurally almost the same as a basket press, simply with the basket swapped out for some press boards, so that was the clear route to take for us. Structurally what was needed was press boards- some large, flat, food-safe objects capable of transmitting several tons of force to the apple in between. We opted for a number of HDPE cutting boards. I plopped them onto our router table and added some channels for the cider to flow down and out as it presses. Plastic scraps got everywhere doing this but the cleanup is worth the extra yield.

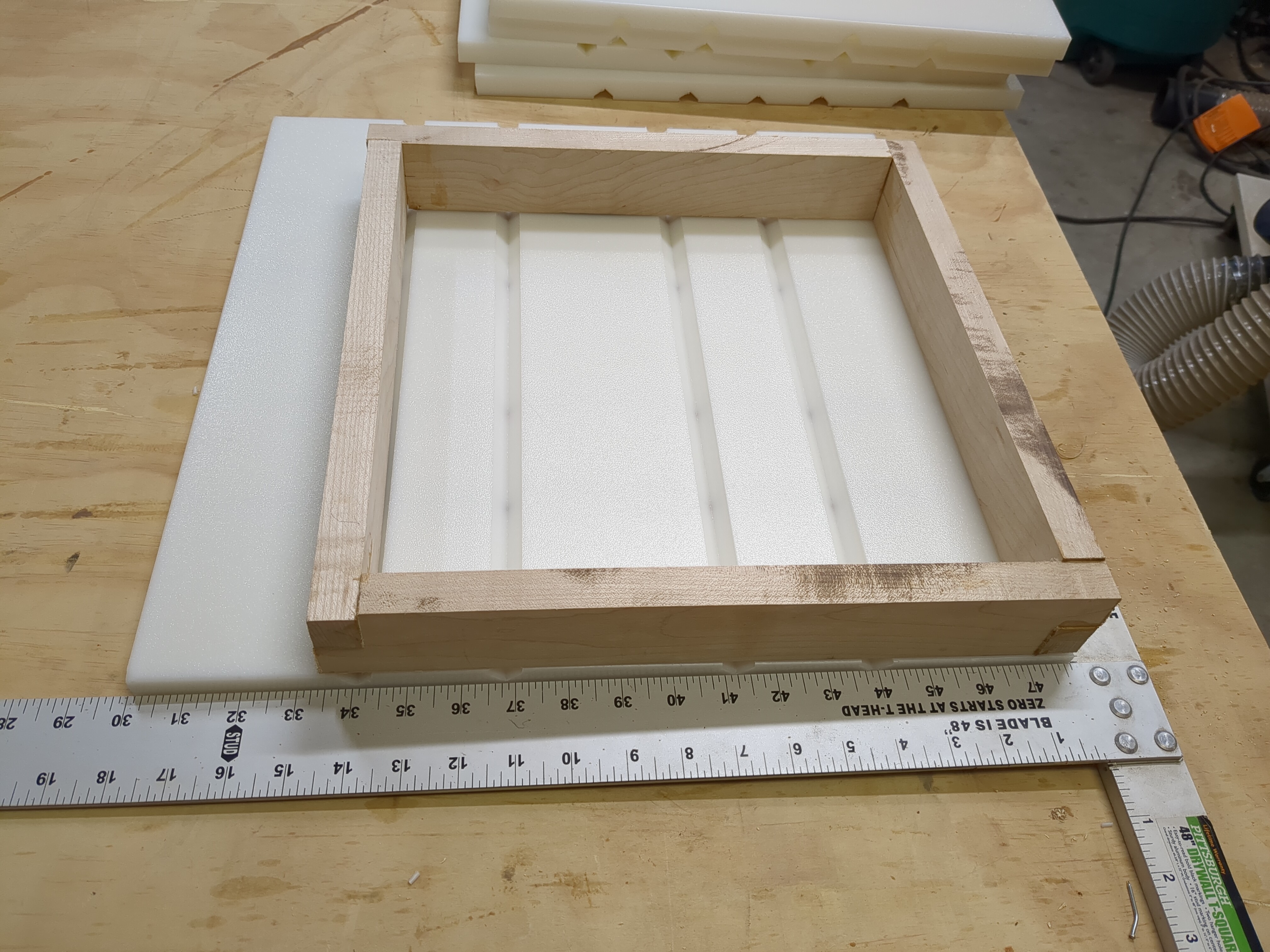

A rack and cloth press also needs a form. That is, a little wooden square that lays on top of the last press block, whether the base or the last HDPE press board, and over which the press cloth is draped and which is filled with apple pulp. When full, the press cloth is folded over the top and the form is removed to be placed on the next press board. The purpose of this is twofold- it shapes the wrapped pulp (called a "cheese") into approximately the same square shape as the press boards, and it is useful as a coarse measuring tool to put the same amount of pulp into each cheese. We had some pieces of scrap maple left over from when we made the press, and these were easy to turn into a square.

I also had to do a surprise second upgrade. The crossbeam at the top of the press, you may recall from the post about it, was made from a 4x4 of red oak. A very strong beam. It turns out that hydraulics are stronger still, and while hand-pumping the jack for a demonstration pressing, the beam decided to take leave of its structural integrity and caused an early end to that season's pressing.

Could I have replaced it with a yet-thicker beam that would maybe someday meet a yet-more-violent end? Yes I could have, but I opted instead to go to a scrap metal yard and buy a section of I-beam, cut to length, which has the dual benefit of being much stronger than anything I could use made of wood, and also if it were to fail would gradually deform rather than exploding. Cider is great but it's not so great to risk your face geting ripped off by a flying chunk of wood.

The Results

The new and improved rack and cloth press was put into operation, and indeed the pomace left over is now much drier to the touch than it was before. Last year someone brought by a hydro press, and we determined that the hydropress was actually slower, more difficult, lower volume, less efficient than the rack and cloth. So it looks like it's here to stay. As an added bonus, the old basket press absolutely chewed through press bags, on the order of several per day having holes ripped in them. Since a rack and cloth press has no sharp edges on which to catch fabric, the same press cloths I bought the first season of rack and cloth pressing are still all intact, three cider seasons later, and I have not needed to open up the spares I had assumed I would need.

Chatting later with another friend who swears by her hydropress, it sounds like a lot of people have a secondary pump that increases the bladder pressure far beyond what comes out of the hose. It makes sense this would work well and produce high efficiency.

So after replacing the pain-to-make basket with some sheets of HDPE, I now have a press that can press about 50% more apple at a time, and get more juice out per unit input. I'm fully on team rack-and-cloth now and cannot recommend a basket press to anyone wanting to press more than a single-digit number of liters. Maybe someday I'll be able to build a continuous belt press, but for now I think this is about as good as it gets. Future gains for me will come from better grinding or other pre-processing, not from the press. I hear good things about the Spiedel grinder, but it costs nearly two thousand dollars, so I would love to be able to make a custom version of it out of a standalone electric motor and a stainless steel grinder blade; I'm not sure how to source such a thing though.

If you read this far, thanks for reading! If you're thinking of building your own press and want information, or just want to chat, please reach out and say hi!